From tap to cooler, our certified technicians keep your entire system spotless and performing at its best, ensuring every pour is as fresh and consistent as the first.

Clean Lines. Fresh Beer. Every Time.

Line Cleaning & Maintenance

A clean, well-maintained draught system protects product quality, reduces waste, and keeps your taps pouring at peak performance. Our technicians follow a standardized cleaning protocol on every visit: full system inspection, chemical cleaning of lines, faucet breakdown and sanitation, FOB and coupler servicing, and verification of temperature, gas balance, and flow rates. We document each service to ensure full compliance with brewery and industry standards.

Routine maintenance is not optional. Beer stone, microbial buildup, and temperature fluctuations degrade flavour, increase foaming, and cost your business real money. Consistent, professional cleaning prevents equipment failures, extends the life of your system, and ensures every pint tastes exactly as the brewer intended.

Draught Pro delivers reliable, schedule-driven service backed by trained technicians, proper chemicals, and proven processes. The result is simple: better beer, less downtime, and a system you can count on.

Reliable Support, Whenever You Need It!

Our 24-hour, 7-day-a-week emergency service ensures that we're always available to address any issue you're having. Whether it's a sudden loss of cooling, a stubborn foam problem, or a complete system failure, a skilled technician is only a phone call away.

Need immediate help?

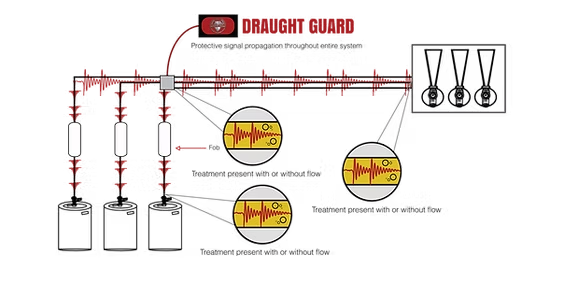

Draught Guard

Draught Pro is the sole authorized provider of Draught Guard in Atlantic Canada. This industry-leading technology actively protects your draught system between cleanings by inhibiting biofilm growth, improving line hygiene, and maintaining consistent pour quality. Our technicians handle full installation, calibration, and ongoing verification to ensure the system performs exactly as designed.

Being the exclusive regional provider means you receive certified support, proper setup, and access to the latest Draught Guard advancements. When combined with routine line cleaning, Draught Guard delivers a higher level of protection, reduces buildup, and helps extend the life of your equipment.

For venues committed to serving exceptional beer every time, this added layer of system protection is a meaningful competitive advantage proudly available only through Draught Pro.

Omnipresent, systemwide treatment.

Draught Guard's proprietary technology propagates a low-frequency signal throughout the entire beer line, no matter the length of run and regardless of flow. This omnipresent and oscillating treatment signal prevents the growth of biofilm and calcium oxalate, or beer stone, and protects your beer while served on tap.

Benefits Of Draught Guard

-

Draught Guard not only maintains line cleanliness between caustic flushes, but can improve overall draught quality. Paired with regular faucet/coupler maintenance, Draught Guard delivers the highest form of draught quality.

-

With Draught Guard in place, you can feel assured that the beer will taste, smell, and appear as it was originally crafted to.

-

By stabilizing draught quality between cleanings, Draught Guard helps reduce waste and generate meaningful savings. Find out how much you can save by implementing Draught Guard in your system.

-

Extend the life expectancy of your lines with the use of less chemicals.

-

Craft breweries make it a priority to to implement sustainable practices. With extended cleaning cycles, hundreds if not thousands of gallons of water can be saved each year.

-

Line cleaning is a part of doing business. We're not arguing that, nor are we replacing it. Rather, we've delivered a more cost efficient means of cleaning lines.

-

Paranoid that your beer and reputation are at risk on tap? Not sure your employee did a thorough job? Can't get into the stadium to clean this week? Draught Guard has you covered in between caustic cleanings.

FOMR

Custom mixed bio-digester that is foamed on surfaces to eliminate all organic materials on the floors/walls – these are what lead to mold, pest problems, sticky floors or slip and fall.

Specialized hospital grade virucide/fungicide/bactericide/mold killer mixed with our foaming agents and applied to all surfaces. This allows adherence and application into cracks/crevices and areas that are hard to reach – this product kills mold and can prevent it forming again.

Surfaces are treated with our specialized equipment and all mold is removed / site is cleaned – waste is packed/transported safely so as to not contaminate other surfaces, etc.

Finishing applications of bio & virucide/fungicide/bactericide/mold killer and any specific issues/areas treated

Deodorizing solutions left in place to provide a pleasant finish and absorb any future odours, etc.

Ideally continue to clean every 6 months but not required

Ice Machine Cleaning

Ice is a food product, and your machine needs the same level of care as any other piece of food-service equipment. Our technicians perform full interior and exterior cleaning, descaling, sanitizing of all food-contact surfaces, bin cleaning, filter inspection, and operational checks to ensure your machine runs efficiently and safely. Each service is completed using industry-approved chemicals and documented for your records.

Regular cleaning is critical. Scale buildup, mold, and bacterial growth can contaminate ice, shorten equipment life, and lead to breakdowns that interrupt service. Consistent professional maintenance keeps your machine producing clear, clean ice and protects your guests and your equipment investment.

Draught Pro provides reliable, scheduled cleaning programs that eliminate risk, reduce costly repairs, and keep your ice machines operating at peak performance year-round.

Discover what Draught Pro can do for you.

Select your service type and we’ll connect you with a Draught Pro technician.